Rondvaart Rotterdam

De leukste manier om

Rotterdam en de havens te ontdekken!

Bestel hier uw tickets

Rotterdam Havenrondvaart

Volwassenen 17,50 | Kinderen 9,80

- 75 minuten incl. audiogids

- Bruisende horeca aan boord

- Ontdek alle highlights

Ontdek alle rondvaarten en events

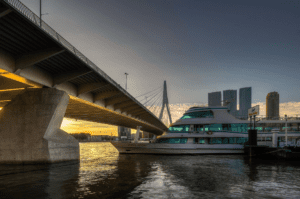

Koninklijke Spido biedt het hele jaar door vanaf de voet van de Erasmusbrug rondvaarten, dagtochten en themacruises aan in Rotterdam. Ontdek onze rondvaarten.

Rondvaart Rotterdam 75 min

Ervaar de imposante skyline vanaf het water. De allerleukste manier om Rotterdam te ontdekken!

Moederdag High Tea Cruise

Breng Moederdag door met een heerlijke high tea op het water en leuk presentje voor uw moeder.

Dag & Thema cruises

Ontdek ons aanbod unieke belevenissen aan boord terwijl de stad aan u voorbij trekt.

Koninklijke Spido: Al ruim 100 jaar een begrip in Rotterdam

Middenin het drukke verkeer van binnenvaart- en zeeschepen biedt Koninklijke Spido de leukste manier om Rotterdam te verkennen.

Meer over Koninklijke SpidoVeelgestelde vragen

Tijdens de Havenrondvaart van 75 minuten werken wij met een audio explicatie systeem aan boord. Deze is hoorbaar in het Nederlands, Engels, Duits en Frans. Op papier is de explicatie eveneens beschikbaar in het Japans, Chinees, Spaans en Italiaans.

Bij de Uitgebreide Havenrondvaart is de audio explicatie hoorbaar in het Nederlands, Engels en Duits.

Tijdens de dag- en thematochten geeft de kapitein toelichting in het Nederlands. Er is geen audio explicatie aan boord.

Ja, dat kan. Als u online een entreebewijs via Spido.nl heeft gekocht kunt u uw entreebewijs retourneren. Doe een verzoek hiertoe telefonisch op 010-275 99 99. U ontvangt uw aankoopbedrag retour (exclusief boekingskosten) Afvaarttijden kunnen wij kosteloos voor u wijzigen.

Entreebewijzen bijvoorbeeld Dagtochten of Thematocht tickets kunnen 8 werkdagen voor afvaart geannuleerd worden. U ontvangt uw aankoopbedrag retour (exclusief boekingskosten)

Tickets via andere kanalen gekocht kunnen niet door Spido geretourneerd worden.

Catering aan boord is aanwezig en voor eigen rekening tenzij anders aangegeven.

Gezien de drukte in het hoogseizoen adviseren wij deze echt online te kopen om teleurstelling aan de kassa te voorkomen.

Eigen consumpties zijn niet toegestaan aan boord.

Zowel aan boord als aan de kassa kunt u alleen met pin/ creditcard betalen.

Het Familie ticket is beschikbaar (2 volwassenen & 2 kinderen 4 tot 11 jaar) inclusief een leuk informatief activiteiten boek voor de kinderen.

Dit ticket is alleen online te boeken en geeft automatisch korting bij het invoeren van 2 volwassenen en 2 kinderen.

Reserveren noodzakelijk vanaf 20 personen. Graag per mail op reserveringen@spido.nl of telefonisch niet via ons online ticketsysteem. Voor groepen vanaf 20 personen zijn er Lunchtassen te bestellen.

Honden zijn toegestaan op deze rondvaart van 75 minuten, mits aangelijnd. Reserveer vooraf een ticket a € 3,00 per hond. Hulphonden (mits aantoonbaar) zijn te allen tijde gratis.

Zowel de wederopbouw als de vernieuwingsdrang waarmee Rotterdammers hun stad vormgeven, maken Rotterdam tot een fascinerende plek om te bezoeken. De vele attracties, monumenten, de havens en de architectonische hoogtepunten maken telkens weer indruk. Deze dynamische stad moet je gezien hebben, vanaf de rivier en wandelend door de straten en boulevards, over de havenkades en in de parken.

Bent u nieuwsgierig naar wat u echt moet zien in Rotterdam? Ontdek hier must sees van de Maasstad.

Spido beschikt over een moderne vloot waar u binnen en buiten kunt genieten van een rondvaart.

Al onze moderne rondvaart schepen zijn rolstoelvriendelijk (max 200 kg)

Aan boord van onze schepen bevinden zich invalidentoiletten.

Ook is het mogelijk om zich te verplaatsen naar het buitendek. Het skydeck is helaas niet bereikbaar voor rolstoelen.

Voor de Rotterdampas en/ of Ooievaarspas moet er online vooraf een tijdslot gereserveerd worden.

Telefonisch is dit niet mogelijk.

-

- Ga naar de website: www.spido.nl

- Ga naar ‘Bekijk tickets’.

- Kies voor Rotterdampas online + aantal personen invoeren.

- Selecteer gewenste datum en tijd.

- Toevoegen aan winkelmandje.

- Plaats bestelling.

- Vul hier uw NAW gegevens in en klik op bevestig bestelling.

- Ga met uw pas langs de kassa om deze te laten chippen.

Reserveren voor Rotterdampas is alleen online mogelijk en niet telefonisch of per email.

Na de reservering moet u langs de kassa om uw Rotterdampas te chippen.

U kunt dus niet direct aan boord.

Klik hier voor meer informatie over de Rotterdampas/ Ooievaarspas.

Koninklijke Spido is gevestigd op het Willemsplein 85, 3016 DR ROTTERDAM

Touringcarbussen

Er is gratis parkeergelegenheid voor touringcarbussen, nabij de afvaartplaats op het Willemsplein.

Personenauto

Uw personenauto kunt u parkeren in de naastgelegen Erasmusgarage ( willemsplein 100).

– Parkeertarieven Erasmusgarage:

€ 0,50 per 13 minuten (06.00 – 22.00 uur) / € 1 per 52 minuten (22.00 – 06.00 uur). Dagtarief is € 23,00.

– Betaalmogelijkheden: contant, chipknip, pinpas of creditcard.

– Doorrijhoogte: 1.90 m.

– Via www.parkereninrotterdam.nl kunt u voordeelkaarten bestellen.

Uw personenauto kunt u parkeren in de naastgelegen APCOA Scheepvaartkwartier garage (Van Vollehovenstraat 5 G, 3016 BE ROTTERDAM)

– Parkeertarieven Scheepvaartkwartier €2,50 per 60 minuten tot €20,00 per dag.

– Doorrijhoogte 1.90 m.

– Meer informatie over deze garage vindt u hier

Parkeren op straat

In het gehele centrum is betaald parkeren, u betaalt € 5,52 per uur.

Betalen voor parkeren is mogelijk met een Parkeerapp op uw telefoon bijvoorbeeld Parkline, Parkmobile.

Vervoersmiddelen hoger dan 1.90 m die niet in de garage passen kunnen langs de weg parkeren.

Parkeren op de Touringcar parkeerplaats op eigen risico.

P+R (park & ride)

De meest gemakkelijke en voordelige manier om te parkeren is op een P+R terrein buiten het centrum. Op een P+R-terrein kunt u uw auto of motor gratis parkeren wanneer u met een OV chipkaart verder reist.

De meest bekende P+R terreinen zijn; P+R Slinge, P+R Kralingse Zoom, P+R Capelsebrug en P+R Alexander. Klik hier voor alle locaties in en buiten Rotterdam op de website van de gemeente Rotterdam.